Note that the intended toughening mechanism here is not the microcrack toughening with formation of a fracture process zone (FPZ), as usually described in the literature.

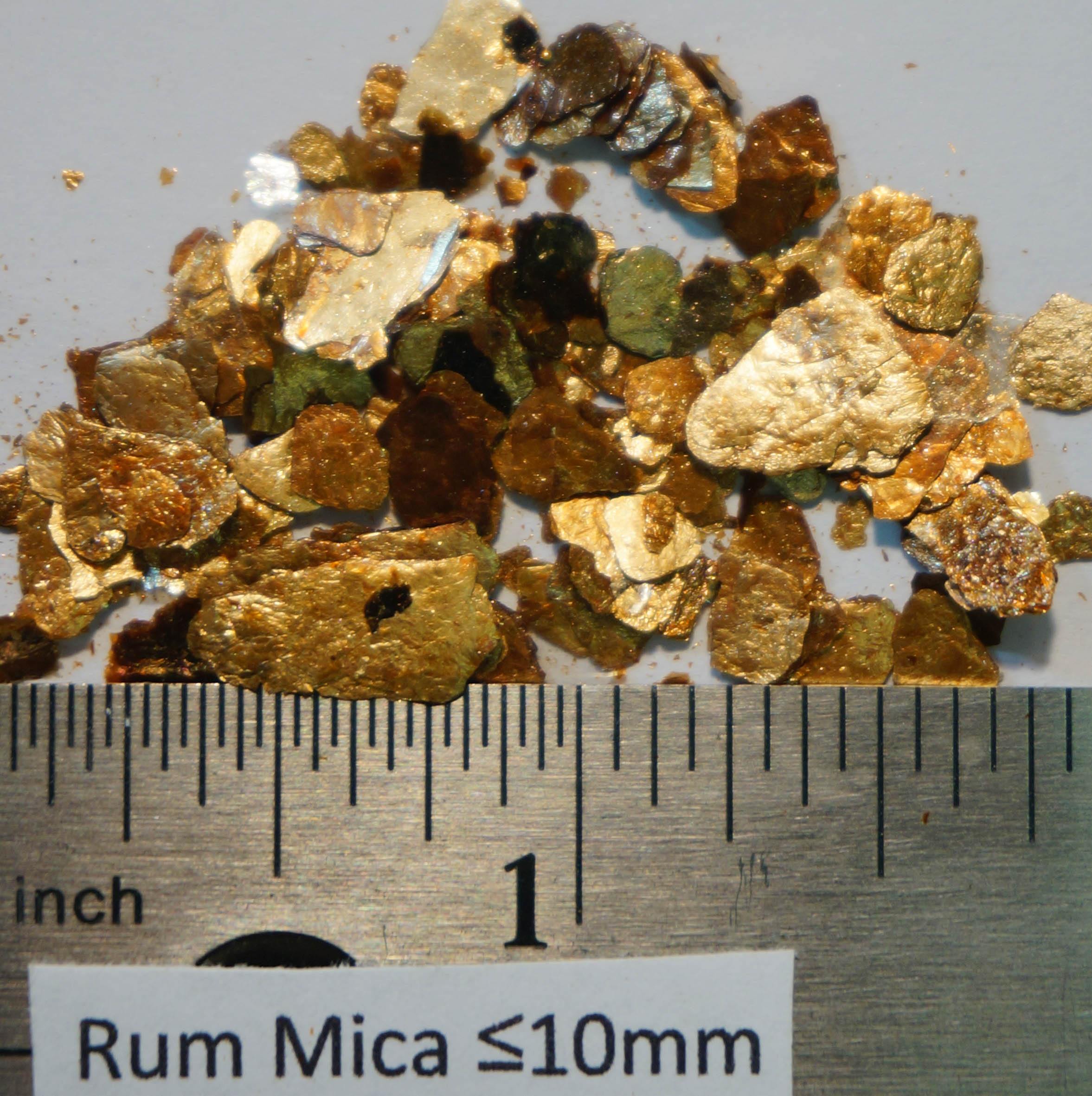

Mica flake crack#

Hence by controlling size and content of the artificial microcracks in order to maintain stable crack propagation, additional energy may be consumed in developing a number of concurrent crack surfaces. Such uniform distribution of microcracks encourages the development of multiple concurrent cracks, which will delay the localization of failure. The basic principle is the homogenization of the matrix through the uniform distribution of mica flakes as source of fictitious microcracks. This study investigates an alternative toughening mechanism based on “microcrack formation”. Appropriate choice will depend on application but in any case it will result in an individual optimization problem, in which the volume fraction, size and distribution of each selected components in the mixture, are the design parameters. The resulting fibre reinforced cementitious composites (FRCC) may display somehow distinct mechanical behaviour and failure mechanisms. Complexity arises in the tailoring of cost-effective composite, when one takes into consideration the wide range of mechanical, physical and chemical properties of fibres, as well as properties of different particulate matrices. Some recently proposed approaches to optimize efficiency of toughening mechanisms include tailoring of the matrix composition and particle size. A third mechanism to be considered is called crack deflection, in which toughness is elevated by increasing the area of the fracture surface. Several approaches have been proposed to improve the toughening mechanism of fibre reinforcement, in which the key element was to increase the bond strength and friction at fibre–matrix interface.ĭeveloping other energy consuming mechanisms in the composite matrix may further increase the material toughness.

The first phase may be described as the work done in destroying the initial (chemical) bond between the matrix and fibre and the second phase as the work done by sliding friction (frictional bond) while the fibre is extracted from the matrix. Yet for performance reasons, due to current advances in cement and fibre technology resulting in considerable differences in matrix–fibre interactions, fibre pullout may be better regarded as a complex two-phase toughening mechanism. Fibre reinforcement falls into the latter category. Evans distinguished toughening mechanisms for ceramic materials according to overall mechanical behaviour into two categories: process zone formation and bridging. The role of toughening mechanisms is to consume energy, thus increasing the total energy required for fracture. Pullout of the fibre is preferred as a toughening mechanism, since it consumes much more energy and prevents catastrophic failure. Hence, the fibre keeps bridging the crack until one of its ends is completely extracted from the matrix or the fibre breaks. Debonding activates a combination of elastic and frictional stress transfer mechanisms. As the load increases, shear may gradually destroy the chemical bond along fibre and matrix interface. During initial stage of loading, the fibre–matrix interaction is elastic, with stress transfer occurring through shear at the interface. The presence of fibres results in minimal increase in stiffness prior to cracking and holds the matrix together after cracking. Though fibres improve general post-peak mechanical behaviour, they were introduced mainly to arrest propagation of cracks. The use of fibres in the composite matrix emerged as a strategy to partially offset the low strain capacity of concrete. Consequently, concrete technologies have branched into design of pseudo-ductile materials.

Recent concerns in concrete design are shifting towards safety and durability of concrete structures. Gains in compressive strength have usually resulted in even lower strain capacity and resistance to crack propagation. Yet, concrete has two main detrimental properties as structural material, namely low tensile strength and poor fracture toughness.

Constant increases in size of concrete members lead to advances in concrete technology particularly focusing on developing high-performance concrete, which possesses high compressive strength and durability.

0 kommentar(er)

0 kommentar(er)